MIAB welding demonstration machine

Magnetically impelled arc butt (MIAB) welding is a "single shot" method of joining pipe and tube which is used in highly automated factory production lines in high volume industries such as automotive manufacture.

Welding Process

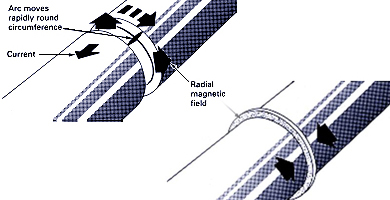

The speed of rotation of the arc is extremely rapid (around 150m/s). After the ends are heated, they are then pressed together and this welding forging 2 causes any molten metal upon the heated surfaces to be forced out of the joint, along with oxides and other impurities.

Welding Overview

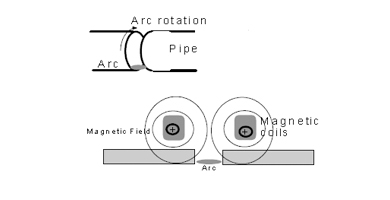

ERW relies on electrical resistance to generate the heat necessary for welding whereas MIAB welding uses an electric arc. The arc is rotated around the pipe circumference using a magnetic field:- hence the name “Magnetically Impelled Arc Butt Welding

MIABW is a step change in pipeline construction productivity

Achieved through;

- Dramatically reduced manpower and skill required

- Fully computer controlled, thoroughly documented and highly consistent joints

- Single shot welding process requiring no consumables

- Vastly improved productivity in all weathers

Process Overview / Miab Technology

Magnetically impelled arc butt (MIAB) welding is a "single shot" method of joining pipe and tube which is used in highly automated factory production lines in high volume industries such as automotive manufacture

MIAB welding is a welding process similar to Electric Resistance Welding (ERW).

ERW is used for making the long seam weld in oil and gas pipelines.

Both ERW and MIAB welding are autogenous welding processes which means that no filler metal is required.

ERW relies on electrical resistance to generate the heat necessary for welding whereas MIAB welding uses an electric arc. The arc is rotated around the pipe circumference using a magnetic field:- hence the name “Magnetically Impelled Arc Butt Welding”

The speed of rotation of the arc is extremely rapid (around 150m/s). After the ends are heated, they are then pressed together and this Figure 4 - MIAB welding forging 2 causes any molten metal upon the heated surfaces to be forced out of the joint, along with oxides and other impurities. A high quality fusion weld is thus produced.