About MIAB /

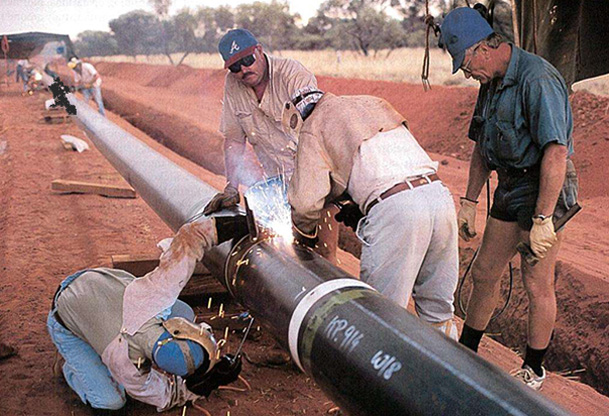

Breakthrough Technology for high productivity welding of gas and oil pipelines

Where is MIABTech now?

- Proved the technology in the laboratory; satisfactory tensile, bending and charpi tests as required for current joining methods

- Built a demonstration field machine

- Constructed two significant lengths of DN150 pipelines

- Successfully hydro tested one of the pipelines

Executive Summary

- Patent Protected Unique Steel Pipeline Construction Technology

- Based on Established and Widely Used Welding Method

- Single shot process requiring no consumables

- Fully computer controlled, thoroughly documented and highly consistent joints

- Three Fold Productivity Improvement in all weathers

- Dramatically reduced manpower and skill required

- Up to 95% Labour Saving

- 36% or More Construction Cost Reduction (Independent Study for SANTOS)

- 12% Capital Cost reduction

- Demonstrated In the Field

- Satisfied Every Test Mandated For Other Welding Methods In AS2885 - 2

- The MIAB Tech team has extensive experience in implementing the technology

Camp Size

- 52 less personnel

- One third camp duration – quarter camp size

- Quarter fly in/fly out cost

- Half machinery requirement

Skills

- 1 skilled welder instead of 17

- Computer based quality control

- Computer controlled welding – consistent quality

- Much reduced defects hence repair costs

The Principal’s Bio Data

The writer is a practicing mechanical, electrical and

mechatronics engineer with the bulk of his

experience in heavy machine design.

He first got involved in the pipeline industry in 1970

when engaged as deputy laboratory manager at

HUMES Ltd steel research laboratory.

The association with pipes continued with work for

HUMETAL, TRANSFIELD, TUBEMAKERS, BHP

the LUCAS Group, ONESTEEL and subsequently

for CSIRO where he was employed as a principal

research scientist and project leader on the SciFi

Pipe project.

He also engaged in research in various fields and has a

string of inventions going back to the 1950s.

He has a suite of MIAB inventions of which only one has

been patented.

A recent non MIAB invention was a method of

continuous equal channel angular extrusion

(CECAP) jointly patented with Monash University.

His latest foray into the pipeline game was the design of

a computer controlled 90 tonne machine for the

onshore deployment of umbilicals and cables on

Barrow Island for the 6Mt/a Chevron gas project.

Two views of the machine on Barrow Island shown

deploying the Gorgon Umbilical.