MIABW is quick for typical DN150 pipes

MIABW construction

- 10 seconds arc time

- Single team, 1 welder

- 1 minute cycle time

- Up to 9km/10 hour shift

- Up to 18km/day

- 2 shifts

Current best & fastest practice

- 12 minutes arc time

- Multiple teams, 8 welders

- 3 minutes cycle time

- 3km/10 hour shift

- 2 shifts not practical

For typical DN450 pipes

MIABW construction

- 20 seconds arc time

- Single team, 1 welder

- 1 minute cycle time

- Up to 9km/10 hour shift

- Up to 18km/day

- 2 shifts

Current best practice

- 48 minutes arc time

- Multiple teams, 17 welders

- 3 minutes cycle time

- 3km/10 hour shift

- 2 shifts not practical

Size range

- DN150 x 4.8 X56 - validated by MIABTech in the field

- DN300 x 10 validated by KUKA in Germany on short air receivers

- DN300 x 8 validated by TWI on short pups in Canada.

- Current technology limit - DN450 x 10

- Undisclosed, patentable, plasma technology will extend this

The value proposition

Cost Savings

- MIAB can deliver significant construction cost savings.

- In 2003 SANTOS commissioned an analysis of the available construction cost savings;

- Bowley report for Santos found savings of 36% or more

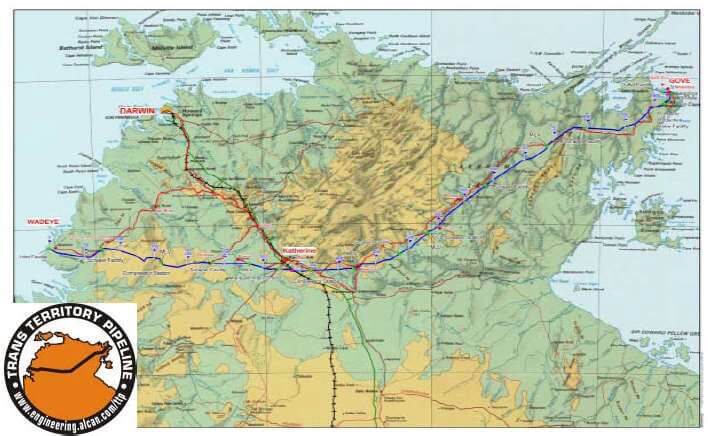

Example - Trans Territory Pipeline

995 km of 450 mm dia - $750,000,000 tender price by courtesy of Andy Lukas of the LUCAS Group

How are the costs reduced?

Example: Trans Territory Pipeline

- Three fold increase in productivity

- Current technology – 330 working days = 2 working years due to monsoon season

MIABW – 110 working days = 1 dry season.

Gas to customer 18 months earlier

Trans Territory Pipeline potential savings:

- Notional capex; $750M

- The Bowley model saving $88M

Other possibilities

- The much higher productivity and lower cost of MIABW construction opens opportunities

- 2 x DN450 uses the same quantity of steel as 1 x DN650 and has the same flow section but a more economic pipe manufacturing process

- Multiple strings provide redundancy and lower cost

Other opportunities

- Potential savings for the yet to be constructed Bunburry to Albany pipeline is around $30,000,000

- The commercial machine to suit this pipeline has been designed and construction ready in 2006

- Expected fabrication and commissioning time for the machine is around 4 months